Electro Magnetic Flow Meter

Electromagnetic Flow Meter velocity sensing, microprocessor based signal converter, sealed housing, flanged tube meter for 1.0 Mpa working pressure, manufactured to highest standard available for mag-meters, equipped with minimum six digit digital totalizers, reading in different units (Kiloliters / Cubic meter) and accurate within 0.5% of Measured value, shall operate within a range of 0.3 m/sec to 4 m/sec and be constructed as follows: Meter tube (Sensor) shall be fabricated from stainless steel tube and use class PN10 flat face carbon steel flanges in accordance with IS 1538. lined with hard rubber/ Polyurethrene/ PTFE preferably by SBR or EPDM. Meter tube shall have a constant nominal inside diameter offering no obstruction to the flow. The accuracy should be inclusive of linearity, hysteresis, repeatability, temperature and pressure effects.

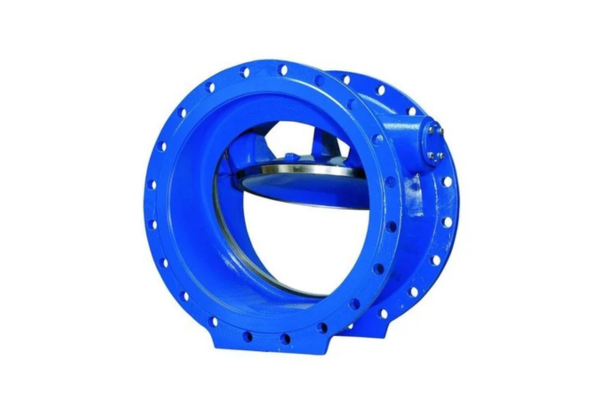

DI Double Eccentric Butterfly Valves

DI D/F Butterfly Valves with GGG 40 or equivalent grade as per IS 3896 (Part 2) 1985 and subsequent revisions Double eccentrically disc with renewable soft seal on the disc and body seat face of Stainless Steel/ nickel weld overlay micro finished with powder or liquid Epoxy coating with minimum thickness of 250 microns applied on both body and disc inside and outside Face to Face dimensions as per AWWA C 504 or BS 5155 or IS 13095

DI DF Slanted Seat Check Valve

DI D/F Slanted seat Tilting Disc Swing Check Valve in single piece body and closed eye disc construction. Hemispherical disc with 59 degree inclination for fast open and closing. Corrosion proof and wear resistent(triple offset) disc face & body seat face, both made of fusion bonded Nickel Chromium weld overlay and microfinished. Body and disc of ductile cast iron GGG-40 or equivalent grade, medium free(dry) shafts of stainless steel and bearings of Zinc-free Bronze, Valve will have provision for internal damping unit for reducing the effects of water hammer/surge, if required at later stage. Electrostatic epoxy powder/liquid coating(EP-P) inside and outside color blue RAL 5005 with minimum coating thickness of 150 microns. Face to face dimensions as per EN 558-1 series 14 and flange connections as per EN 1092-2/IS 1538.

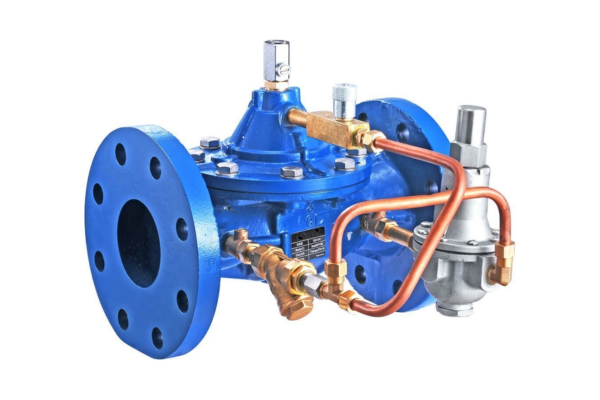

DI Pressure Reducing Control Valve

DI pressure reducing valve body DI Pilots Brass Fittings Brass Tubeing High pressure PP PN16 as per TWAD specification. The automatic pressure reducing valve shall be installed to ensure downstream pressure is maintained as per set point. In case the downstream pressure is higher than set point pressure, the valve shall close to ensure downstream pressure is maintained. It is easy to reset the pressure set point as per

DI Surge anticipating control Valve

Surge anticipating Relief valves against power failure surges or pressure waves caused by velocity changes, quick opening relief easily adjustable pressure setting. The valve will remain closed when line pressure is between the set-points of the two pilots. The valve will open initially when line pressure drops below the setting of the low-pressure pilot to anticipate surges associated with a pump stopping. The valve will also continue to react and remain open when the return high-pressure wave is above the setting of the high-pressure pilot or open when inlet pressure exceeds a pre-determined set-point at which time the valve opens quickly. With high speed discharge, with flange dimension to EN 1092-2/ ISO 7005 [DIN]. Body and cover in ductile cast iron of Grade GGG 40 or equivalent grade. All internal parts & all cover bolts of austenitic alloy steel and gaskets and seals of EPDM of grade W 270 (approved for drinking water) with Electrostatic epoxy powder coating (EP-P) inside and outside color blue RAL 5005 with minimum coating thickness of 250 microns

DI Flow limit Control Valve

DI Flow rate Limit control Valve (PN10/16) with the function to limit the flow rate to a set point. In case the downstream demand increases beyond the set limit, the valve closes down to bring the flow back to set limit. The valve shall have an orifice plate and the orifice diameter is designed based on the set point as per the requirement and installed downstream of the control valve. “Manufacture supply and delivery of DI D/F Diaphragm type own medium controlled Flow rate Limit Control valve with cast body of ductile iron grade GGG-40 or equivalent grade or as per IS 3896-Part-2-1985 customized control cylinder for linear control behaviour or equivalent, performed diaphragm and pull out safe profile sealing ring of EPDM, threaded inserts (CORFIX – to prevent the coating from coming off in the connections area as well as corrosion and incrustations in the control circuit) or equivalent. Flange connection dimensions according to EN 1092, Part 2/ ISO 7005[DIN]/ IS 1538, all parts (Epoxy coating, and diaphragm) in contact with medium are as per KTW and DVGW certified (harmless)/WRAS & NSF approved.

OHT flow control valve

OHT flow control valve with female BSP treaded ends with Stainless Steel Body as per ANSI 202 Grade, Plug, Flange – Nylon 66, Triangular notch type flow control path with opening reference scale arrangements for flow notch and Upstream & Downstream pressure checking spring loaded mouth arrangements. Working Pressure 10 KSC.